Manufacturer of the folder gluer tells the knowledge points about carton making machine

What machine is used to make the box?

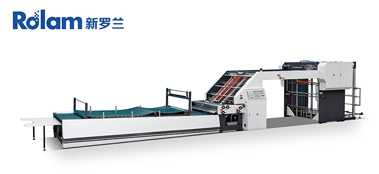

In the packaging machinery industry, the carton-making machine is also called the box-making machine. The main products of the forming machine series are: the carton forming machine and carton forming machine.

Carton making machine is indispensable equipment when making a carton. At present, there are mainly two kinds of carton-forming machines with hot melt glue machines and carton-forming machines without hot melt glue machines on the market.

The carton forming machine with hot melt glue machine has the following characteristics: the face paper is automatically fed to the conveying part; there is a vacuum suction fan under the conveyor belt to control the relative deviation of the glued face paper; the hot melt glue is automatically circulated, stirred, Gluing system; hot-melt adhesive tape automatic conveying and slitting device to complete the four corners of the inner cardboard box at one time; the carton forming part automatically receives the carton to the forming part according to the conveying condition of the carton above the conveyor belt.

Carton making machine without hot-melt glue machine also adopts PLC programmable controller, photoelectric tracking system, touch screen man-machine interface, and implements paper feeding, gluing, cardboard forming, four corners, positioning and fitting, automatic introduction, box feeding, packaging, etc. Edges folded ears and folded forming actions are completed at one time. It has a simple structure, convenient operation, and high speed, and is suitable for the use of large, medium, and small packaging enterprises.

There are manual, semi-automatic, and fully automatic box-making machines. There are also many machines for box-making machines. A complete box-making process requires several machines. The first is the die-cut beer paper machine after paper printing, and then the carton surface paper is glued, using the glue line box gluer, the four corners of the inner box and the corner beating machine, and then the inner box with the corners are glued with good glue The facial paper is positioned and glued to the box, and the visual image positioning robot is used. Manual positioning is also possible. Finally, it is folded into the bubble-forming machine. The complete production process of a carton machine is almost the same.

What is the raw material of the carton?

1. White cardboard

It has the characteristics of high folding resistance and high stiffness. The surface of the whiteboard paper is smooth, the front is white, and the back is generally gray cardboard. This kind of carton is mostly used for packaging handicrafts, small department stores, etc. Whiteboard paper has the characteristics of high folding resistance and high stiffness.

2. Kraft cardboard

It has the properties of wear resistance, pressure resistance, and water resistance. It is one of the main types of paper in our country and belongs to high-quality paper. Kraft cardboard has the properties of wear resistance, pressure resistance, and water resistance, and most of them are mainly used for packaging large objects in life.

3. Corrugated base paper

It has certain elasticity and pressure resistance. The indicators should be controlled. If the moisture content is too small or too large, cracks and paper softness may occur, which will increase the processing cost.

Carton-making machine suppliers tell How are cartons made?

Working principle of automatic carton forming machine:

1. Suction carton

The carton-forming machine is also called the unpacking machine. When the user puts the finished flat carton into the hopper, the unpacking machine will use its own suction cup to suck the carton into the hopper. The force of this force is the step of sucking open the flat carton into a carton.

2. Fold the bottom of the carton

After the unpacking machine sucks and closes the carton, the carton has been basically formed, and the work that needs to be done is to fold the bottom.

3. Carton back cover

After the automatic carton forming machine has gone through the first two links, the forming work has been completed. The above is the working principle of the automatic carton-forming machine. As long as the range of carton size is selected and the speed of unpacking is set, the carton-forming machine can effectively improve work efficiency.