The difference between pre-folding and non-pre-folding of folder gluer

The characteristics of the folder gluer: the production efficiency of the folder gluer should be improved to a higher level. Now there are many packaging manufacturers. Only by starting with the delivery speed can more orders be obtained. Based on the consideration of cost reduction, intermediate production links can be saved, which can save a lot of costs for enterprises in the long run and can also realize the production of small batch orders, which can seize the current market for small batch orders.

6 points for attention of high-speed automatic folder gluer:

1. The operation interface of the folder gluer should be kept clean and cleaned frequently.

2. The glue box of the upper part of this fold should be kept clean and cleaned frequently.

3. It is strictly forbidden to adjust the speed when the governor is stopped, otherwise the belt wear will be very serious.

4. It is best to drive at a slow speed before starting the machine to check whether the machine is abnormal.

5. The inner plate supports, shafts, and rods should be cleaned frequently, and mixed with lubricating oil and butter for better effect, which can shake left and right to prevent rusting.

6. Wipe the mechanical belt with clean water to keep it clean and prevent slipping, especially to prevent it from sticking to the belt. The glue wheel and glue box on the bottom of the hook must be cleaned every day after getting off work, otherwise, the glue in the glue box will freeze, which will affect the gluing effect.

Summary of common problems of high-speed automatic folder gluer:

1. The adhesive and carton data do not match.

2. The pressure is insufficient after folding and gluing, and the pressure time is not long, which is not conducive to the strong paste.

3. The viscosity of the adhesive is not good or the amount of glue applied is insufficient.

4. The sticky part of the carton is processed by the surface such as filming and glazing. It is difficult for the adhesive to penetrate the surface layer and enter the paper, and the carton is difficult to stick.

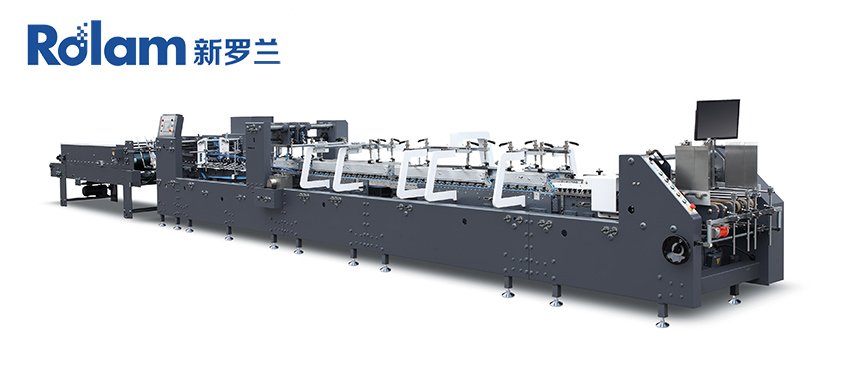

Types of folder gluers:

1. Ordinary side-gluing folder gluer: It has the most basic functions of folding on both sides and attaching on both sides. This folder-gluing machine has the highest proportion in the market and has the widest application range. It is the most basic folder-gluing equipment instead of manual folder-gluing.

2. Folder gluer with pre-folding: ordinary paper boxes are basically square (that is, four sides), ordinary folder gluers and manual folder gluers can only fold two sides, and the other two sides have only indentations but no folding. However, it is not easy to open the carton, and it is easy to jam the automatic loading line. The pre-folded carton is easy to open and suitable for automatic loading and packaging machines, especially for medicine boxes, which are basically pre-folded and glued.

3. Folder gluer with hook bottom: It is a complex equipment among all kinds of folder gluers, and the debugging difficulty is also high. It not only has the functions of the above two types of folder gluers but also can fold and paste the bottom of the box. Boxes pasted in this way are particularly easy to open when in use. And the bottom has been glued, no need to insert the bottom manually, we call it automatic bottom in the industry.

The difference between pre-folding and non-pre-folding of folder gluer

Pre-folding is to fold down the indentation line of the folded, easy to open, hook bottom is to hook up the bottom, no need to insert manually. Some boxes are difficult to open after pasting. Pre-folding is folding the box in advance during the pasting process on the folder gluer to facilitate opening after pasting.