Get In Touch

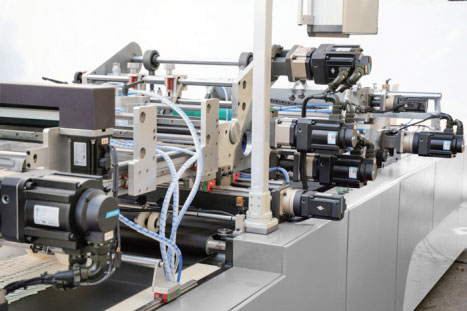

• 9 Sets of Servo Full Motion Intelligent Control

• Rotary Knife Cutting Film

• Air Expansion Shaft With Magnetic Powder Tension Film Unwinding

• Batch Counting of Paper Receiving Tape

• Automatic Deviation Correction System

• Tissue Box Film Middle Cutting Function

• Double Sheet/Empty Sheet Automatic Glue Lifting

• High-precision Point-to-point Positioning

• Paper Jam Automatic Stop

• Printed Film Side Tracking

• Punch Holes On The Film (Optional)

| Model | TC-890 | TC-1200 |

| Machine Speed (Normal Pasting) | 4000-20000pcs/h | 4000-20000pcs/h |

| Paper Length | 140-800mm | 140-1100mm |

| Paper Width | 40-450mm | 40-500mm |

| Film Length | 120-780mm | 120-780mm |

| Film Width | 60-400mm | 60-400mm |

| Thickness of Film | 0.03-0.25mm | 0.03-0.25mm |

| Main Power | 4.5KW | 4.5KW |

| Power of Pump | 17KW | 17KW |

| External Dimension | 2300KG | 3000KG |

| Machine Weight | 6200×1650×1950mm | 6200×2150×1950mm |

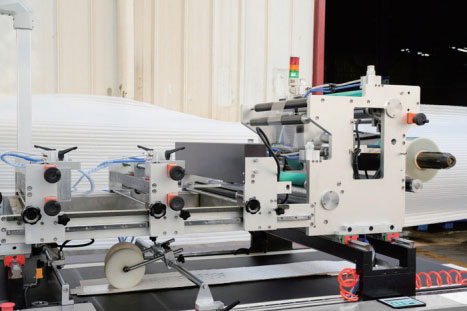

| The whole machine adopts intelligent motion control system (a total of 9 sets of servo systems) and man-machine interface. The close cooperation between the servo and the photoelectric sensor enables the deviation of the product to be effectively monitored and corrected at each parts, and finally make the high quality products that customers need. |

|

| The paper feeding part adopts servo photoelectric to feeding paper, input the length and speed on the touch screen, so that make the paper feeding is fast and accurate. Suitable for cardboard and corrugated paper with laminating, reverse UV, nano UV, oil and water varnishing. In addition, a punching part is reserved, which is suitable for paper output smoothly of thin paper and slightly warped paper. |

|

| The pin paper-feeding part adopts servo control, which can be operated directly on the touch screen,it can change the angle to adjust the connection speed between the paper and the pin, so that make different papers can be fed more stably and smoothly. |

|

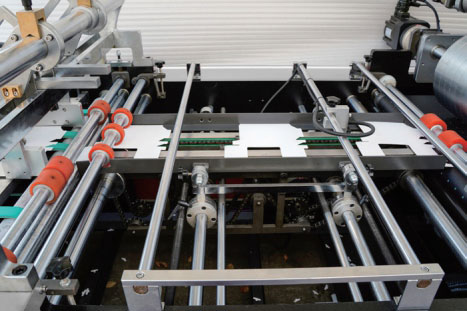

| The suction and conveying part adopts a combination of servo and blower, which can change the wind force according to different paper specifications , so that make the paper was always adsorbed on the conveyor belt stably. |

|

| The gluing part is composed of servo motor, cylinder, photoelectric, solenoid valve, 304 stainless steel roller, glue separating guide plate, side limiter and gluing roller, which can be easily pulled out for setting and cleaning conveniently. Adjustable glue separating guide plate to control the glue range and outflow volume. After stopping machine, the cylinder can lift the gluing roller and drive it with another independent servo motor to avoid the glue from solidifying. The gluing roller can freely adjust its position axially and radially without stop the machine. Once meet with double sheets or empty sheet in the gluing part, the gluing part have the function of lifting glue, which prevents the glue from contacting the suction belt effectively. |

|

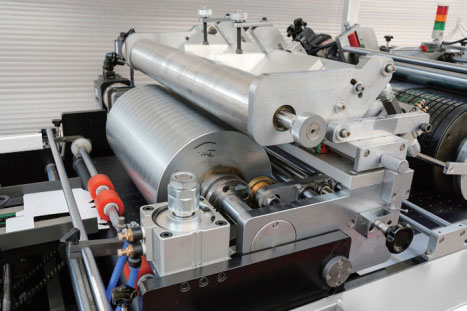

| The film cutting, normal pasting parts are controlled by servo motor and automatic deviation correction, with characteristic of high precision and fast speed . The film mechanism also adopts servo control, which can be jogged as a whole, fine-tuned left and right, and quickly aligned with the window. |

|

| The film feeding part uses the air expansion shaft to load the film.The tension control function makes the servo film feeding more stable, eliminating stretching and reducing inertia. At the same time, it is also equipped with the function of printed film side tracking and stop due to lack of film. |

|

| The collecting part has the counting function, which can be counted in batches, and has automatic machine stop function when has paper jam. |

|

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

In the packaging industry, carton design is critical for product protection, branding, and logistics efficiency. Two common types of cartons are four corner cartons ...

Flute Laminating Machines are pivotal in the packaging industry, facilitating the enhancement of corrugated board by laminating it with diverse materials. This proce...

Paper folding machine is an efficient and automated equipment widely used in printing, publishing and bookbinding industries. It folds paper in a predetermined way t...

GET A QUOTE