What are the advantages of folder gluer machine with the traditional manual gluer?

What are the advantages of the folder gluer compared with the traditional manual gluer?

What are the advantages of the folder gluer compared with the traditional manual folder gluer? In the past, the use of hand-glued boxes often required huge labor costs, long production time, and product quality could not be guaranteed. The folder gluer folds the printed and die-cut cardboard into a shape and then sticks it on the paste. The machine pastes the box instead of the manual box, which reduces labor costs and improves efficiency.

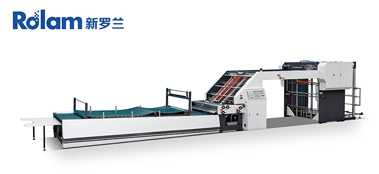

What is a folder gluer machine?

In today's society, the exquisiteness and product quality of the packaging box industry has attracted widespread attention. When it comes to packaging boxes, we have to mention the folder gluer. The application of the folder gluer is the last process of packaging box processing.

Folder gluer machine parts are divided into paper feeding part, pre-folding part, hook bottom part, forming part, and box pressing part.

The parts of the folder gluer are divided into the paper feeding part, pre folding part, hook bottom, forming part, and box pressing part. The groove bottom function does not even have pre-folding, and the better ones have pre-folding. Of course, most folder gluers now have pre-folding. Of course, you must use a groove bottom folder gluer to make hook bottom boxes. Hexagonal and heterosexual boxes can be made, but glue spraying systems and other devices need to be configured.

Take you to understand the classification of folder gluers on the market

1. Ordinary side-gluing folder-gluing machine: It has the most basic functions of folding on both sides and sticking on both sides. This kind of folder-gluing machine accounts for the highest proportion of the market and has the widest application range. It is the most basic box-gluing equipment to replace manual box-gluing.

2. Folder gluer with pre-folding: Ordinary cartons are basically square (that is, four sides). Ordinary folder gluers and manual gluers can only fold two sides, and the other two sides have only indentations but no folds. However, it is not easy to open the carton, and it is easy to jam the machine on the automatic loading line. The pre-folded cartons are easy to open and are suitable for automatic loading and packaging machines, especially for medicine boxes, which basically use pre-folding folder gluers.

3. Folder gluer with hook bottom: it is the most complicated equipment among all kinds of folder gluers, and the difficulty of debugging is also the highest. It not only has the functions of the above two types of folder gluers but also can fold and paste the bottom of the box. Boxes glued in this way are particularly easy to open for use. And the bottom has been glued, no need to insert the bottom manually, we call it automatic bottom in the industry.

The principle of folder gluer machine

The working principle is that the cardboard is conveyed to the lower end of the pressing block through the conveyor belt, and the limit pressing block is driven by the cylinder to press down and fix. After fixing, the folding plate 1 is folded inward. Transport in the guide groove, fold the cardboard in the guide groove at the rear end through the dispensing rod and set the dispensing head to dispense glue on the upper surface of the folded cardboard. After the dispensing is completed, the folded cardboard is placed on the auxiliary bead. Folding plate 2 folds the cardboard in the front guide groove so that the cardboard on the pressing block and the cardboard on the auxiliary pressing block are better bonded, thus greatly improving work efficiency and product quality while reducing labor costs.

Maintenance and maintenance

1. The machine should be kept clean and cleaned frequently.

2. Wipe the mechanical belt with clean water to keep it clean, and anti-skid, especially to prevent sticking to the belt. The rubber wheel and the glue box on the bottom of the hook must be cleaned after getting off work every day, otherwise, the glue in the glue box will freeze and affect the gluing effect.

3. The glue box of the upper part of the fold should be kept clean and scrubbed frequently.

4. It is strictly forbidden to adjust the speed when the governor is stopped, otherwise the belt will be severely worn.

5. The support, shaft, and rod of the inner row board should be cleaned frequently, and it is better to use it with lubricating oil and butter, and it can be shaken left and right to prevent rust.

6. Before turning on the machine, it is best to drive slowly and check whether there is any abnormality in the machine.

Structure description of folder gluer machine

The structure of the automatic folder gluer includes a conveyor belt. The front and rear sides of the conveyor belt are sequentially provided with extending limit plates and inwardly folded folding plates 1 from left to right. The guide groove at the end, the limit pressing block corresponding to the position of the folding plate 1 is arranged above the conveyor belt, the cylinder assembly is arranged on the limit pressing block, the folding plate 2 folded backward is arranged on the guiding groove at the front end, and the folding plate 2 at the rear end is guided A forward-folding dispensing rod is arranged on the groove, and a dispensing head is arranged on the dispensing rod.

The inner wall of the guide groove at the rear end is provided with an auxiliary bead, and the inner wall of the folding plate 2 is provided with a pressing block. When the folding plate 2 is folded inward, the pressing block corresponds to the auxiliary bead.

The extension limiting plate and the folding plate 1 at the front end are longer than the extending limiting plate and the folding plate 1 at the rear end, the folding plate 1 is longer than the guide groove, and there is a distance between the guide groove and the conveyor belt.

The glue dispensing rod is obliquely corresponding to folding plate 2, and the glue dispensing rod is on the left side, and folding plate 2 is on the right side.