Automatic Folder Gluer: Understanding the Difference Between Cartons and Hexagonal Boxes

Introduction

In the packaging industry, carton design is critical for product protection, branding, and logistics efficiency. Two common types of cartons are four corner cartons and six corner cartons, which have different uses depending on their structural integrity and purpose. With the advancement of automation technology, automatic folder gluers have revolutionized carton production, ensuring precision and speed.

This article explores the differences between quads and hexagons, their applications, and how automatic folder gluers optimize production.

1. What is four corner cartons?

The quad is the most traditional and widely used packaging solution. As the name suggests, it has four corners and is folded from a single sheet of corrugated or cardboard.

Main Features

Simple structure: Made from a single sheet of die-cut cardboard folded into a rectangle or square.

Common uses: Shipping boxes, retail packaging, and standard cartons.

Advantages:

Cost-effective and easy to produce.

Suitable for light to medium-duty products.

Compatible with Automatic Four Corner Gluing, ensuring fast and efficient assembly.

Limitations:

Lower structural rigidity compared to hexagonal cartons.

Not suitable for heavy or fragile items that require additional support.

2. What is a six corner cartons?

six corner cartons (also known as six corner cartons or double-walled cartons) have six corners, making them more durable and stable. These cartons have additional covers or reinforcements on the corners.

Main Features:

Higher Strength: Extra corners provide better stacking strength and impact resistance.

Common Uses: Luxury packaging, electronics, cosmetics, and high-end retail products.

Advantages:

Provides superior protection for fragile or heavy items.

Premium appearance, ideal for enhancing brand image.

Higher production efficiency with Automatic Hexagonal Folder Gluer.

Limitations:

More complex manufacturing process than four-corner cartons. - Higher material and production costs.

3. The main difference between four-corner and six-corner paper boxes

| Features | Four-corner paper boxes | Six-corner paper boxes |

| Number of corners | 4 | 6 |

| Strength | Medium | High |

| Cost | Lower | Higher |

| Application | Transportation, retail | Transportation, retail | Luxury goods, fragile items |

| Production speed | Faster (automatic four-corner box gluing) | Slightly slower (hexagonal box gluing requires high precision) |

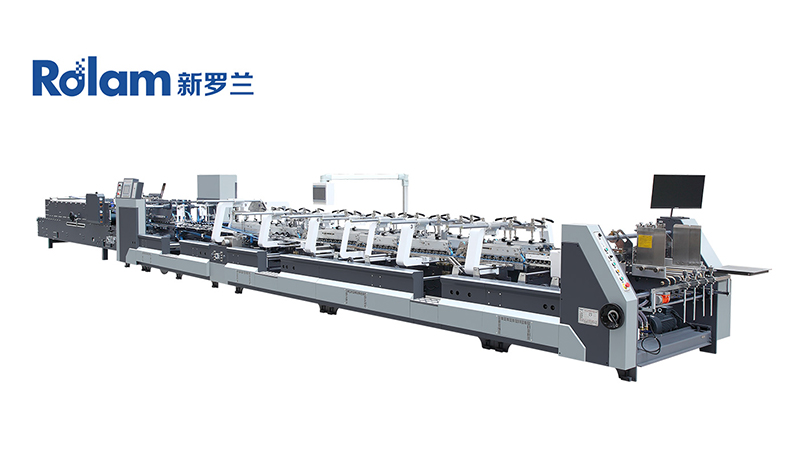

4. Gaoke fully automatic four-corner/hexagonal box gluing machine

Gaoke not only provides high-quality box gluing machines, but also provides comprehensive support for your production. It can provide technical training to help employees better understand the equipment, standardized spare parts system, and all spare parts used meet quality standards. Any missing parts can be replenished in time to ensure the operation of production.

Cost-saving solution: One machine that can handle both four-corner and six-corner cartons is more economical and space-saving than purchasing two separate machines.

Multi-variety operation: The ability to quickly switch between four-corner and six-corner carton production is ideal for packaging companies that frequently switch production lines.

Gaoke Automatic 4&6 Corner Folder Gluer adopts a servo motor control system, and the guide plate has a hookless structure that automatically locks the bottom. From paper feeding to forming, the whole process is highly efficient and coordinated, which greatly shortens the cycle and can also achieve fast delivery.

5. Conclusion

The choice of four-corner carton or hexagonal carton depends on product requirements, budget and packaging aesthetics. Four-corner cartons are suitable for general use, while hexagonal cartons provide excellent protection and a high-end appearance.

By using Automatic 4&6 Corner Folder Gluer, manufacturers can optimize production, reduce costs and maintain high quality standards. Investing in the right equipment ensures that companies can efficiently meet market needs while providing durable and aesthetic packaging solutions.

Understanding these differences can help brands make informed decisions, improve packaging strategies, and enhance the customer experience.