Get In Touch

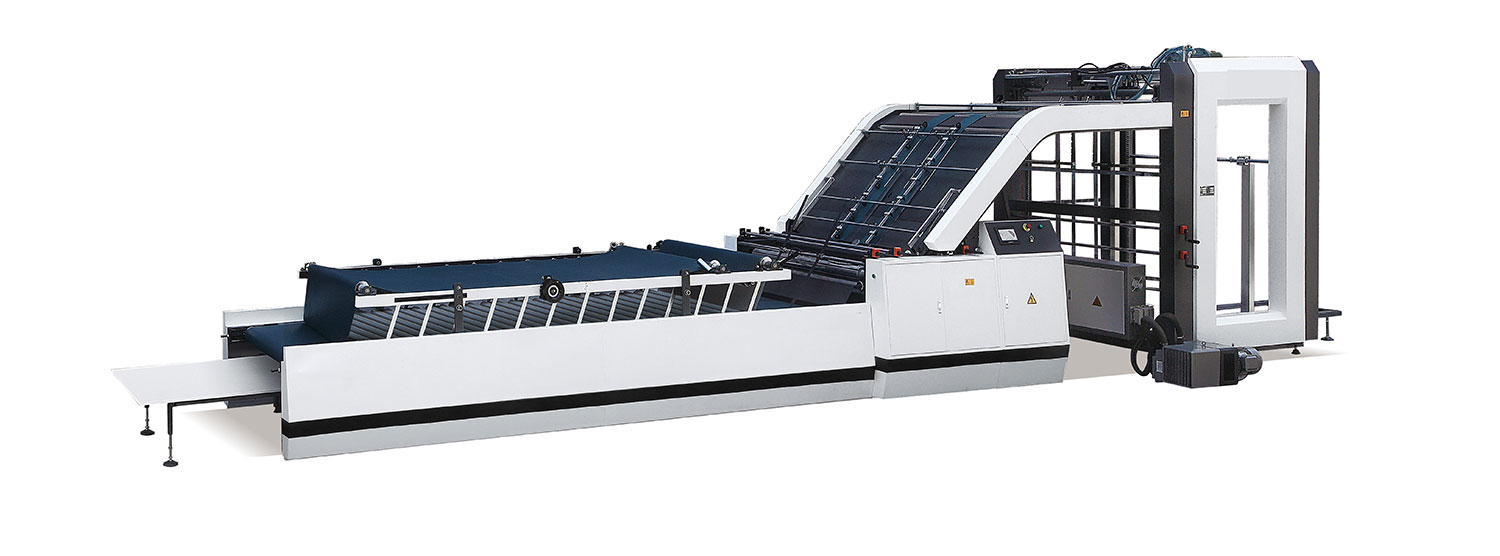

Advanced automatic tracking technology, according to the size of the paper automatically adjust the relevant parameters, so that the machine is always running in the best condition

Unique front gauge positioning system, accuracy and the bottom paper never exceed; top paper exceed adjustable

Equipped with high precision high speed automatic feeder, strengthening type paper feeding device, feeding smoothly.

Using the principle of offset printing machine side gauge positioning, error correction for about top paper stack and feeding process;

Bottom paper using suction automatic feeding, can adjust wind strength in the touch screen, and is equipped with a belt humidifying function;

Standby stack table can pile paper under non-stop situation, along the rail into the elevator, high working efficiency

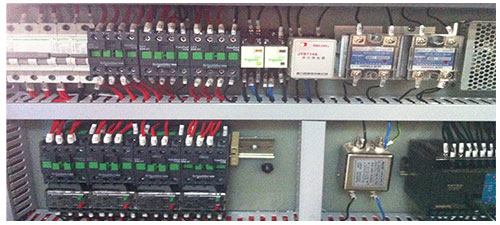

Imported electrical components, to ensure the stability of the circuit system. PLC tracking technology, automatic fault alarm;

Fully automatic glue supplementary system, can automatically replenish the loss of the amount of glue, and cooperated with the glue recycling

Independent water tank control cycle, ensure the bottom paper back dry, at the same time cleaning up roller、glue receive tank and back glue tank;

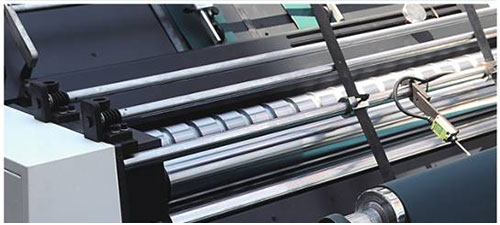

Single side adjustment of the roller pressure, and equipped with a dial gauge, the replacement of the bottom paper onestep- to- reach.

|

Model |

YB-1300E |

YB-1450E |

YB-1650E |

|

Max Sheet Size |

1300×1250mm |

1450×1250mm |

1650×1450mm |

|

Min Sheet Size |

400×400mm |

400×400mm |

400×400mm |

|

Top Sheet Thickness |

150-600g |

150-600g |

150-600g |

|

Bottom Sheet Thickness |

A、B、C、E、F Corrugated paper, Industrial paperboard |

||

|

Max Speed |

6000Sheets/hour |

6000Sheets/hour |

6000Sheets/hour |

|

Fitting Precision |

±1mm |

±1mm |

±1mm |

|

Dimensions |

11.5×2×2.4M |

11.5×2.2×2.4M |

11.5×2.4×2.4M |

|

Machine Weight |

5000kg |

5500kg |

6000kg |

|

Machine Power |

10KW/380V |

11KW/380V |

12KW/380V |

Top Sheet Feeding MechanismHigh precision high speed automatic feeder, feeding smoothly. |

|

|

Pressure Regulation PositioningSingle pressure regulation, to ensure that the two side pressure be same |

TransmissionFloating design of press, no need to adjust the pressure |

|

|

Electrical SystemMain electrical components are imported brands |

Pre-stack PartStandby stack table can pile paper under non-stop situation, |

|

|

Side Positioning (Option)Side Gauge Positioning, error correction for |

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

In the packaging industry, carton design is critical for product protection, branding, and logistics efficiency. Two common types of cartons are four corner cartons ...

Flute Laminating Machines are pivotal in the packaging industry, facilitating the enhancement of corrugated board by laminating it with diverse materials. This proce...

Paper folding machine is an efficient and automated equipment widely used in printing, publishing and bookbinding industries. It folds paper in a predetermined way t...

GET A QUOTE