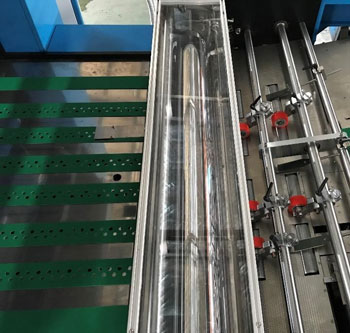

Powder removing mechanism and film laminator

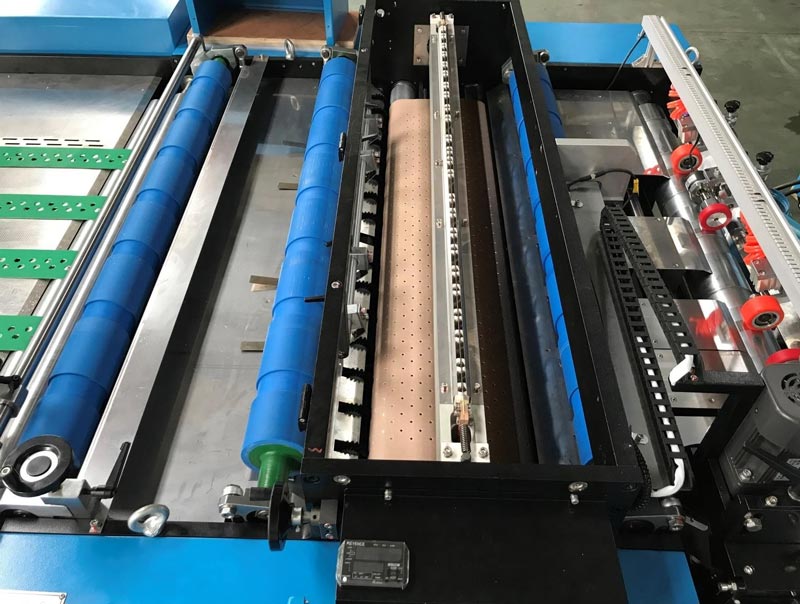

Laminating unit: gluing mechanism

Get In Touch

| Max. sheet size | W1060×L1200mm Min. |

| Sheet size | W320×L290mm Suitable |

| Sheet thickness | 105-500 g/m2 |

| Mechanical speed | 100 m/min, or 9,000 sheets/hour |

| Feeder pile height | 1300 mm |

| Installed power | 70kW |

| Actual production power consumption | 28-35kW/h |

| Overall dimensions | 11200×2100×2900mm |

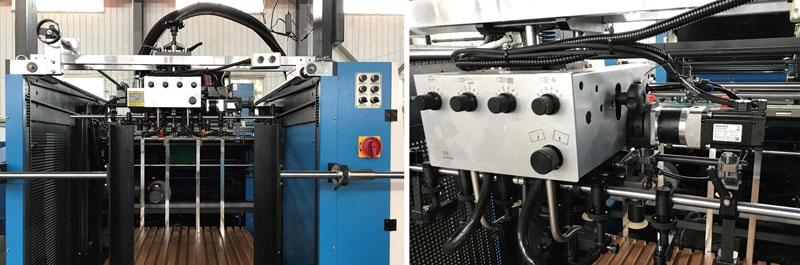

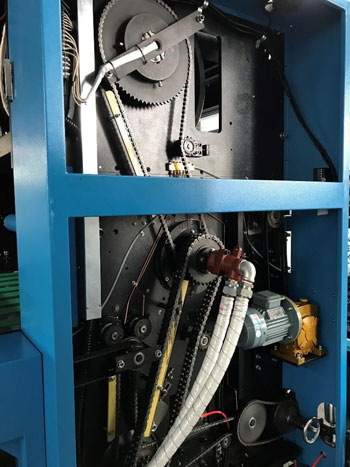

KFM-106MC, photos of workshop

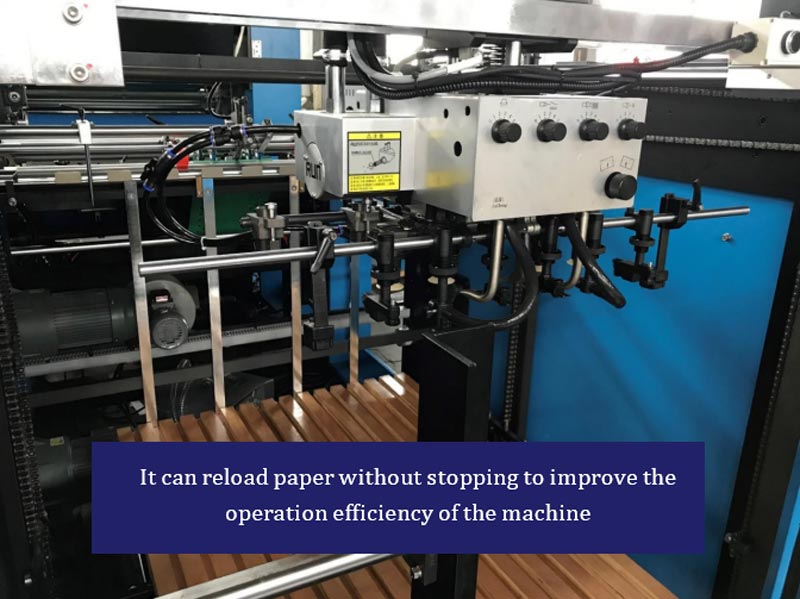

Servo motor is used to control the overlap size, which can be controlled within ± 2mm;

Four suction and four delivery Feeder head, the paper straightness can reach ± 2mm;

It is driven by shaftless servo motor with long service life. The front and rear positions of Feeder can be automatically adjusted.

The overlap joint adopts servo technology to ensure the paper feeding accuracy;

Feeder bridge crossing adopts the whole conveyor belt without paper jam.

Including double guarantees of air suction and pressing wheel, high-speed paper feeding and no paper displacement.

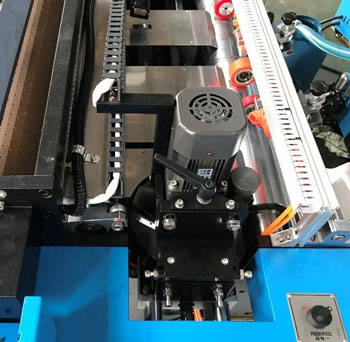

Electric powder removing mechanismPowder removal mechanism: single electric powder removal, automatic constant temperature heating. There will be dust on the surface of the printed matter, which will affect the quality of the lamination. You can choose the electric powder removal mechanism. |

|

|

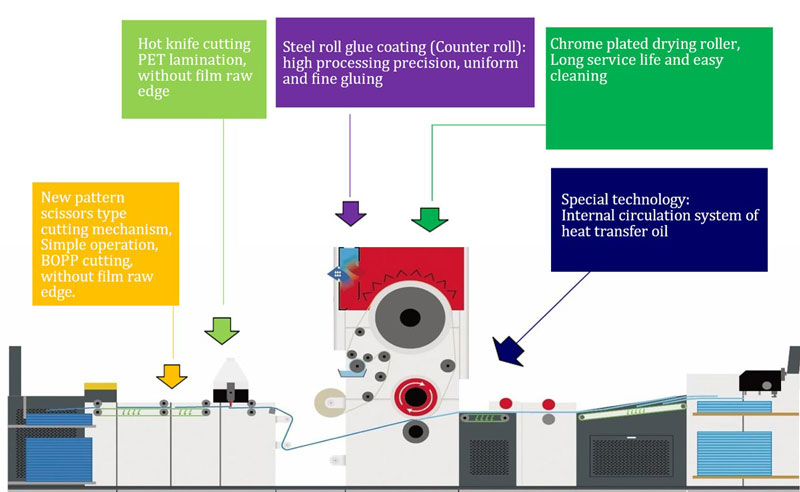

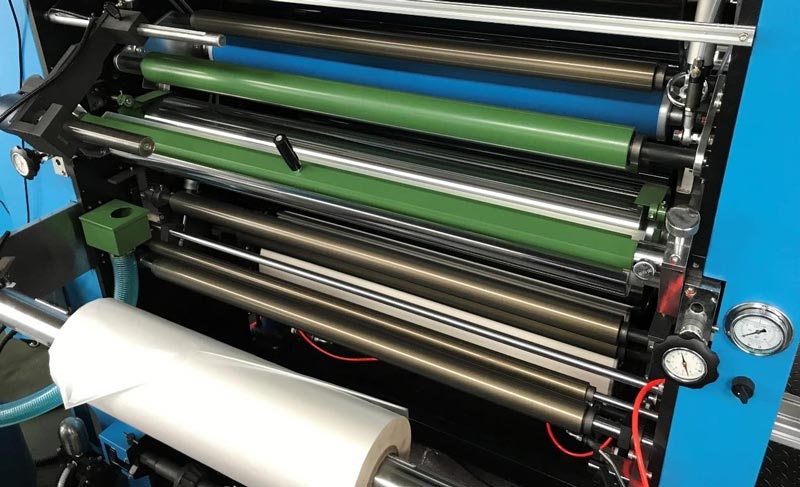

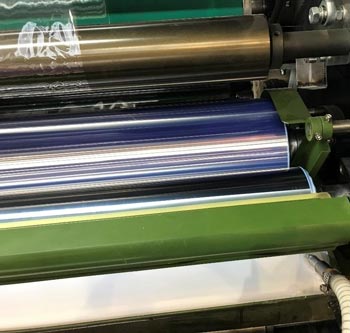

Film laminator unitIt is the core part of a film laminating equipment. The main technical difficulties include: manufacturing and processing accuracy of key parts such as super mirror pressing steel roller, main pressure rubber roller and large-diameter drying roller, what glue coating method is used to save cost and ensure film laminating quality, how to maintain constant temperature and pressure throughout the film laminating process, and how to save energy cost, These key technologies directly affect the quality of laminated products and the actual interests of customers. |

Special technology: heat transfer oil roller internal circulation system of mold temperature machine

Advantages: less temperature difference on the rolling surface, good constant temperature effect in high-speed operation

|

The large-diameter roller for drying the film adopts advanced heating lamp to keep the temperature constant, and the roller surface temperature is balanced and lasting. Combined with hot air to dry the film, the water-based glue can be cured quickly to achieve the purpose of high-speed film lamination; The roller surface adopts non adhesive high temperature resistant material technology, which has long service life and easy cleaning; |

|

Special technology: heat transfer oil roller internal circulation system of mold temperature machine

Advantages: less temperature difference on the rolling surface, good constant temperature effect in high-speed operation

|

The temperature of the mirror heating roller with a diameter of 380mm is constant by the mold temperature machine; There is a hot oil circulation mechanism inside the roller; The roller diameter is large, the temperature is average, the heat constant temperature effect is good, the lamination hot pressing time is long, and the lamination effect is good. |

Special technology: heat transfer oil roller internal circulation system of mold temperature machine.

|

The glue coating roller adopts steel roller With imported high-precision bearings, the glue on the roll surface is uniform, suitable for high-speed operation and wear-resistant surface; Glue coating accuracy can be controlled within ± 0.0025mm; High precision operation, no movement, no glue rod. |

|

Fly-cutter |

Hot knife cutting |

|

|

|

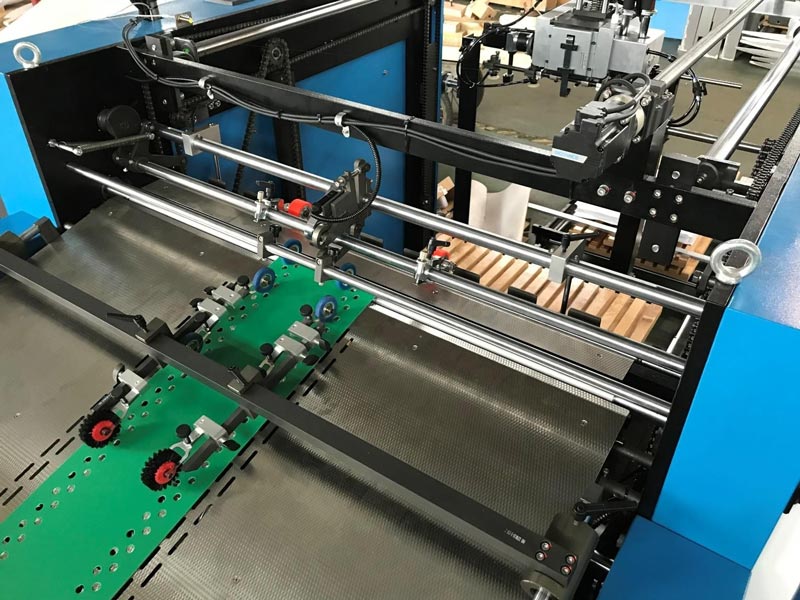

Sheets drawing and cutting machineFlattening mechanism: Thin paper unfolding mechanism to prevent thin paper from rolling up after film laminating; |

New pattern scissors type cutting mechanism:

It adopts unidirectional (one-way) lifting paper drawing roller technology, which is suitable for high-speed film lamination cutting of various sizes, with stable effect, simple operation and no film raw edge;

Reasonable structure and simple operation

Two way, single sheet or multi sheet pneumatic paper beater

The conveyor belt has wave pressing function, which can increase the paper stiffness in thin paper production, and quickly and stably transfer and receive paper;

The paper receiving table is equipped with deceleration function to prevent thick paper from damaging the paper edge;

When the paper is double, it includes a rejection mechanism. In case of double sheets or continuous sheets, the photoelectric signal feedback is detected, and the paper receiving belt accelerates instantaneously to cooperate with the blowing action to make the double sheets fly away from the paper receiving table.

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

In the packaging industry, carton design is critical for product protection, branding, and logistics efficiency. Two common types of cartons are four corner cartons ...

Flute Laminating Machines are pivotal in the packaging industry, facilitating the enhancement of corrugated board by laminating it with diverse materials. This proce...

Paper folding machine is an efficient and automated equipment widely used in printing, publishing and bookbinding industries. It folds paper in a predetermined way t...

GET A QUOTE