Get In Touch

Imported high-end stainless ensures a smooth conveyance.

Imported thin feeding belt, strong and durable.

Enhanced sprocket for grippers chains, ensure the high speed running.

Built-out delivery brush adjustment device ensures the convenient adjusting.

Blower controlling system ensures the paper can be neatly delivered under high speed condition.

Servo controlled ball screw pressure adjustment device.

Dual-channel lubrication system ensures the safety.

Synchronized belt driving system equipped with torque limiter.

Non-stop feeding device, pre-stacking-device and automatic non-stop device, shorten the preparing time and improve the efficiency.

Pressing case and plate design makes the makeready fast and convenient.

Front lay, side lay and speed fine tuning device ensures the stable conveyance and reduce the waste.

Touchscreen HMI, real-time monitoring the running condition ensures the adjustment and troubleshooting more convenient.

Input the parameters from the touch screen, automatic programming the auto-step, greatly save the foil.

18 zones temperature controlling system, each zone can be adjusted separately.

|

Max sheet size: |

1050 x 750 mm |

|

Min sheet size: |

400 x 370 mm |

|

Max die cutting area: |

1040 x 720 mm |

|

Die chase inner size |

1144 x 760 mm |

|

Cutting plate size: |

1080 x 736 mm |

|

Max stamping area: |

1020 x 720 mm |

|

Min gripper margin: |

7 mm |

|

Cutting precision: |

≤±0.1 mm |

|

Stamping precision: |

≤±0.1 mm |

|

Max cutting speed: |

300 T |

|

Max cutting speed: |

7500 S/H |

|

Max stamping speed: |

7000 S/H |

|

Foil roll max diameter: |

Φ240 mm |

|

Vertical foil width |

20~1260 mm |

|

Horizon foil width: |

20~720 mm |

|

Vertical foil axle: |

3 pcs |

|

Horizon foil axle: |

2 pcs |

|

Heating area: |

12 pcs |

|

Temperature range: |

0~199℃ |

|

Pre-stacking height: |

1500 mm |

|

Delivery stack height: |

1400 mm |

|

Application: |

Cardboard 0.1-2mm |

|

Corrugated paper ≤4mm |

|

|

Main motor power: |

11 KW |

|

Heating area power: |

24 KW |

|

Total power: |

60 KW |

|

Dimension: |

5600(+1450)x2550(+2050)x2720 mm |

|

Weight: |

18.5 T |

|

1.1 Hi-end imported feeder, 4 lift 4 forwarder, the sucker can be adjusted according to different paper, 1.2 Blower on both side for separating the paper。 1.3 Ductile iron wall plate. 1.4 Electromechanical double sheet detector. 1.5 Slope conveyer table, fit thin paper in high speed condition, 1.6 Double side lay with photoelectric sensor. 1.7 Brush wheel and rubber wheel can be adjusted together, improve the efficiency. 1.8 Ultra anti-worn feeding rubber wheel. 1.9 Main/ auxiliary feeding non-stop switch. 1.10 Static electricity eliminator device, ensure the smoothly feeding. |

|

|

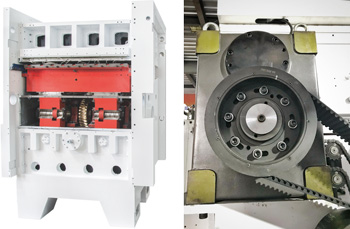

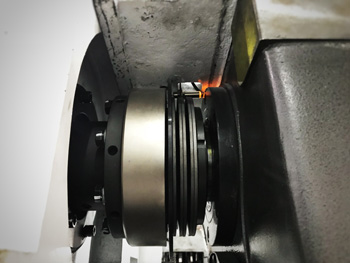

| 2.1 Pressure bearing parts are enhanced high strength ductile iron QT500, high strength and never deform. 2.2 Special processed alloy crank shaft. 2.3 Ultra anti-worn worm and worm gear. 2.4 Pneumatic clutch and SMC rotary joint imported from Japan. 2.5 Oil and air pressure meter to monitor the oil pressure and air pressure, in case of low pressure, the machine will alarm and stop. 2.6 High accuracy intermittent box. 2.7 Die chase in position detector, improve the accuracy, pneumatic chase lock system, electrical pressure adjustment. 2.8 HRC50-53 die cutting plate. 2.9 Pre stretched imported gripper chain, improve the accuracy and stability, improve the accuracy and stability, special side positioning device ensure all the grippers are in one line. 2.10 Ultra hard TI-AL alloy gripper bars. |

|

|

|

|

|

|

|

3.1 Input data in the industrial PC, 3.2 Imported servo motor and control system, 3.3 Temperature of 18 heating zone can be adjust separately, 3.4 Electrical pressure control system, 3.5 Blower device to device the paper and foils. 3.6 Foil breaking detected system. 3.7 Inner and outer foil collection device. 3.8 Special material honeycomb plate, |

|

|

|

|

|

|

4.1 Automatic aligning device, blower in both side 4.2 Touch screen monitor in delivery section indicates the necessary data, 4.3 Photoelectric sensor ensures the neat delivery. 4.4 Automatic delivery lift control system. 4.5 Automatic auxiliary delivery device. 4.6 Main chain protection device. 4.7 Delivery failure alarm. 4.8 Counter and note inserter. 4.9 Gripper bar tensioner buffer device. |

|

|

|

5.1 The stripping section in combined with upper, middle, lower three frames. The frames can be pulled out. It makes the adjustment more convenient and safe. 5.2 Stripping device can either be stripping pins or male/female plate |

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

Flute Laminating Machines are pivotal in the packaging industry, facilitating the enhancement of corrugated board by laminating it with diverse materials. This proce...

Paper folding machine is an efficient and automated equipment widely used in printing, publishing and bookbinding industries. It folds paper in a predetermined way t...

Folding and gluing machine is an automated equipment for folding and gluing paperboard, paper boxes, paper bags and other paper products. It is widely used in packag...

GET A QUOTE