Get In Touch

Adopt European feeder technology, suction adjustable, stable, precise, good paper applicability.

Non-stop feeding, pre-stacking and delivery mechanism can shorten the auxiliary time, improve the efficiency.

Human-friendly designed die frame and baseplate, makes installation, adjustment convenient.

Pneumatic die locking device, die frame fixed more steadily, accurately and time saving.

Front lay, side lay, feeding device fine tuning device, paper positioning more accurate.

Double, crooked, empty optoelectronic position control, ensure the paper in the right position, reduce waste.

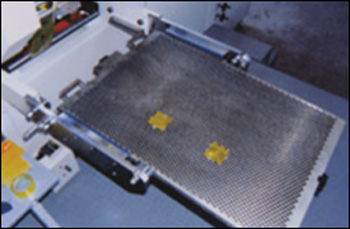

(optional) waste stripping section has 3 linked frames, human-friendly design, easy to install and uninstall the waste stripping plate.

Electronic control modular design, adopt imported electronic components, ensure the accuracy and reliability.

Touch screen man-machine interface, real-time monitor the running situation, makes machine adjustment, trouble shooting more convenient.

Adopt imported server control system for foil stamping, feeding and collecting aluminum foil accurately.

Adopt industrial tablet PC, touch screen input data, realize automatic programming, greatly saving aluminum foil.

Temperature control system has 8 heating area, temperature setting separately, thermostatic control.

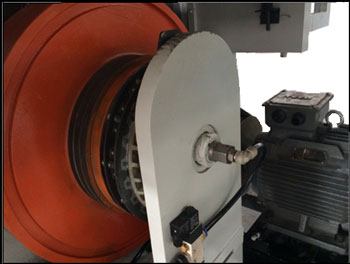

Cycling cooling oil supply system ensure the movement parts get adequately lubricated to ensure the durability.

Adopt fixed quantity at fixed timing oil supply system, ensure the movement parts get adequately lubricated to let better durability.

| Max paper size | 800 x 620 mm |

| Min paper size | 340 x 280 mm |

| Max cutting size | 770 x 600 mm |

| Die frame inner size | 820 x 628 mm |

| Cutting plate size | 826 x 628 mm |

| Max bronzing size | 780 x 600 mm |

| Min gripper needle size | 7 mm |

| Cutting precision | ≤±0.1 mm |

| Bronzing precision | ≤±0.125 mm |

| Max cutting pressure | 200 T |

| Max cutting speed | 7000 S/H |

| Max bronzing speed | 6500 S/H |

| Foil roll max diameter | Φ250 mm |

| Crosswise foil width | 15~600 mm |

| Horizon foil axle | 2 pce |

| Heating area | 8 pce |

| Temperature range | 50~199 ℃ |

| Pre-stacking height | 1150 mm |

| Delivery stack height | 1000 mm |

| Cardboard | 0.1~2 mm |

| Corrugated paper | <4 mm |

| Main motor power | 7.5 KW |

| Heating area power | 16 KW |

| Total power | 45 KW |

| Dimension | 【L (+ pre-stacking )x W(+ platform)x H】 |

| AEM-800TQ | 4350(+1360)x2200(+1300)x2260 mm |

| AEMQ-800T | 5150(+1360)x2200(+1300)x2260 mm |

| AEM-800TQ Weight | 9T |

| AEMQ-800T weight | 10T |

|

European technic precise feeder, |

|

|

Double side lay (pull and push). Feeding device fine tuning, non-stop adjust. Electronic double detector. |

|

|

|

Main, secondary feeding device no-stop switch. Wear-resisting PU pressing wheel. Dual purpose loader. |

|

|

Feeding time fine tuning device. Additional carriage rod 1 set, carriage plate 2 set. (optional) pre-stacking device 1 set. |

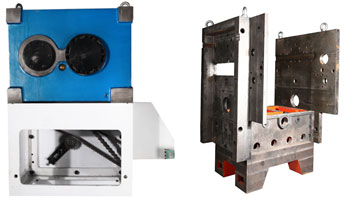

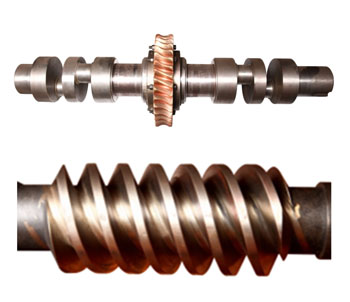

| Pressure-bearing part is made of high ductile iron QT500, high strength, never deform. Alloy crankshaft with special process treatment. Wear resisting worm, worm gear. |

|

| Convenient die flipping device. Cycling lubrication oil supply system with high pressure oil pump from Taiwan High precision interval device. |

|

|

Pneumatic brake clutch device from Italy Japanese SMC rotary joint. Import gripper bar chain. Pneumatic die locking device. |

|

High hardness, strength Ti-Al alloy gripper. Precise pressure adjust device. PLC and man-machine interface from Taiwan. Additional gripper 1set,cutting die 1set,die frame 1 set. |

| Industrial tablet PC, screen touch input data, realize automatic program optimization, saving foils. |

|

| Imported servo motor and control system, precisely feeding foil. Separate setting temperature of 8 heating area, thermostatic control. |

|

|

Electronic pressure control system, during bronzing, if there is no paper, there is no pressure. |

|

Convenient crosswise foil placing device. Special material honey comb heating plate helps locating the bronzing plate. |

|

Adopte RTCr0.8 heating resist cast iron, no deformation while heating, high strength and high durability. |

|

Automatic arranging device, Digital display touch screen in collection section Control panel for human-friendly operation. |

|

Optoelectronic sensor makes the stack neat Collection automatic lift control system. Secondary manual collection Main chain protection device. Roll back prevent device. Non-stop collection device |

|

If you have any enquiry about quotation or cooperation, please feel free to email us every@gaokemachine.com or use thefollowing enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products

Significant global service network coverage

State-of-the-art machining centers

Exceptional precision Experienced team

Expertise in assembly and design

Machines are available with customization options

Efficient installation and maintenance services

Remote troubleshooting support

Online consultation available 24/7

In the packaging industry, carton design is critical for product protection, branding, and logistics efficiency. Two common types of cartons are four corner cartons ...

Flute Laminating Machines are pivotal in the packaging industry, facilitating the enhancement of corrugated board by laminating it with diverse materials. This proce...

Paper folding machine is an efficient and automated equipment widely used in printing, publishing and bookbinding industries. It folds paper in a predetermined way t...

GET A QUOTE